Wie wählt man den richtigen Quarzresonator aus?

Release time: 2024-12-04

Crystal resonators are commonly used frequency sources in electronic devices, and their stability and accuracy are critical to many applications. When choosing a suitable crystal resonator, you need to consider the following key factors.

1.Operating frequency

First, you need to clarify the operating frequency required by the device. Different applications have different frequency requirements, and common frequencies range from a few kilohertz to hundreds of megahertz. Choose the right frequency according to the application scenario to ensure that the crystal resonator can provide the required stable signal.

2.Frequency accuracy and stability

Frequency accuracy and stability are one of the most important indicators when choosing a crystal resonator. Frequency error is usually measured in ppm (parts per million), which indicates the magnitude of frequency deviation. High precision crystal resonators have very small frequency deviations. Frequency stability is related to temperature changes and time aging, and its temperature coefficient and aging rate need to be considered when choosing.

3.Operating temperature range

Different application environments may involve different temperature conditions. The operating temperature range of the crystal resonator is usually indicated in the data sheet, and some high-quality crystal resonators are designed to adapt to a wide temperature range (such as -40℃ to +85℃). Select the appropriate temperature range according to the actual use environment of the device.

4.Load capacitance and driving capability

The load capacitance of the crystal resonator affects its operating frequency, so it is necessary to select an appropriate load capacitance according to the circuit requirements. At the same time, the driving capability of the crystal resonator also needs to match the requirements of the circuit to ensure the strength and stability of the output signal.

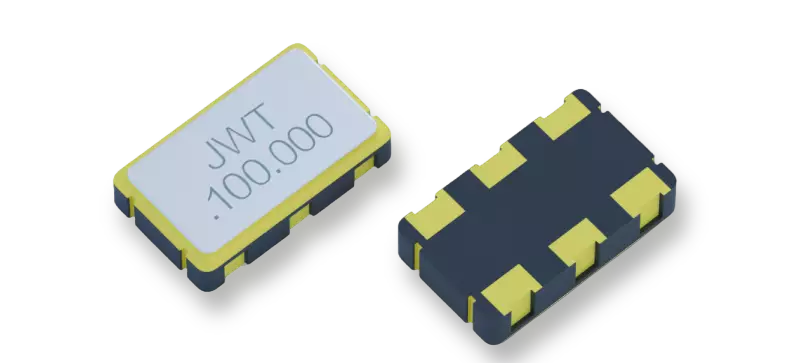

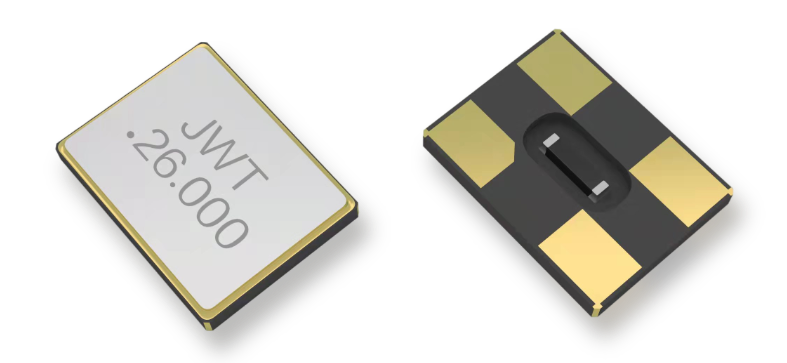

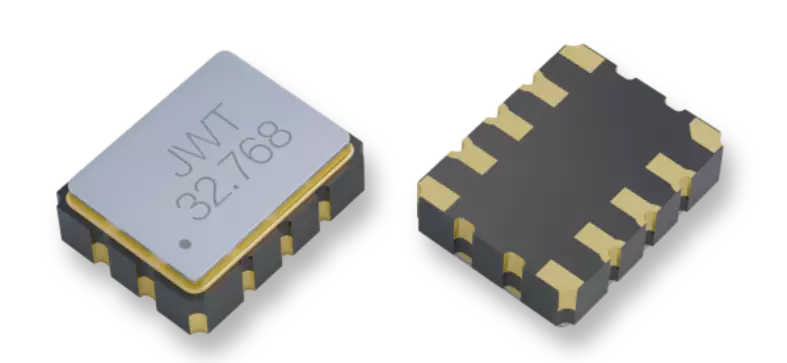

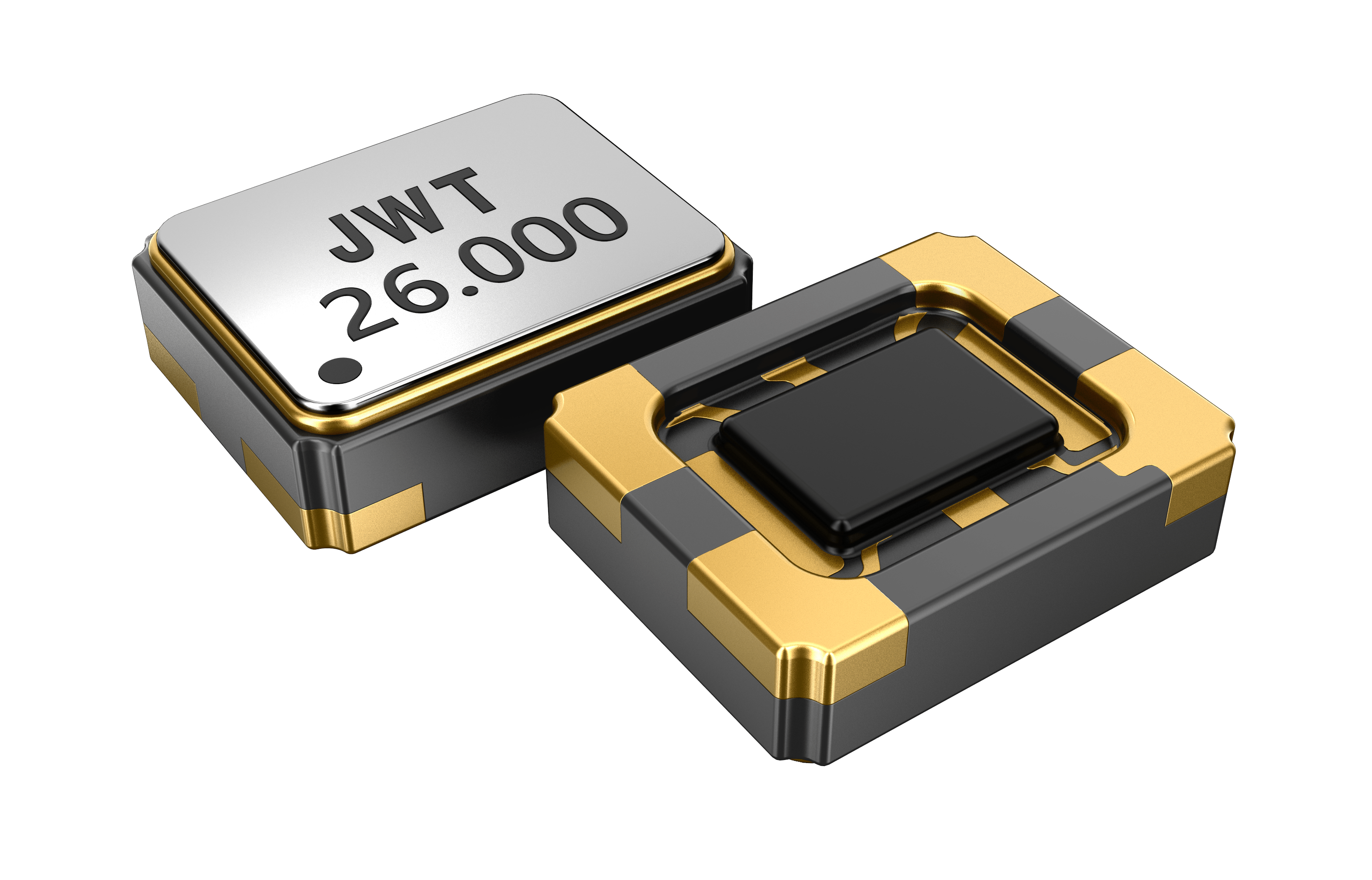

5.Size and package type

When selecting a crystal resonator, the package size and shape are also very important, especially in space-constrained applications. Common package types include metal tube packages, ceramic packages, and SMD (surface mount) packages. Select the appropriate size and package type according to design requirements.

6.Cost and delivery cycle

For mass-produced electronic products, cost and delivery cycle are practical factors that must be considered when selecting a crystal resonator. Ensure that the selection not only meets the performance requirements, but also controls costs to avoid affecting production plans due to supply delays.

Selecting a suitable crystal resonator requires comprehensive consideration of factors such as operating frequency, accuracy stability, operating temperature, load capacitance, etc. according to the application scenario. Through reasonable selection, the long-term stable operation of the equipment can be guaranteed and the reliability and performance of the product can be improved.